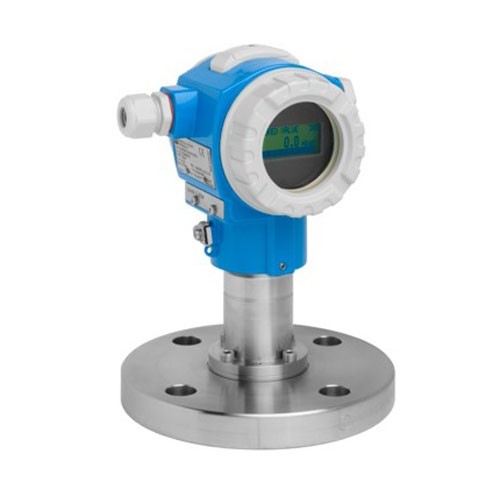

PMC71 Absolute and gauge pressure

- Product Item : PMC71-6BC1M1RDAAA

- Category: Pressure

- Measuring Principle:Hydrostatic

- Characteristic / Application:Digital transmitter with capacitive sensor and ceramic membrane Modular transmitter Long term stability Enhanced safety via self diagnostic functions Secondary process bar

- Supply / Communication:4...20mA HART: 10,5...45V DC Ex ia: 10,5...30V DC PROFIBUS PA / FOUNDATION Fieldbus: 9...32V DC

- Pressure measuring range:100mbar...40bar (1.5psi...600psi)

Absolute and gauge pressure Cerabar S PMC71

Digital pressure transmitter with oil-free ceramic sensor for measurement in gases or liquids

|

The Cerabar PMC71 digital pressure transmitter with capacitive, oil-free ceramic measuring cell is typically used in the process and hygienic applications for pressure, level, volume or mass measurement in liquids and gases. It guarantees high degree of system safety thanks to vacuum-proof ceramic membrane with integrated breakage detection. Quick Setup with adjustable measuring range allows simple commissioning, reduces costs and saves time. SIL2/3 according to IEC 61508. |

Benefits

-

Best fit for vacuum applications and applications with corrosive and abrasive media

-

Process safety through membrane breakage detection

-

Overload-resistant high purity ceramic sensor (99.9% Al2O3)

-

HistoROM data management concept for fast and easy commissioning, maintenance and diagnostics

-

Easy menu-guided commissioning via local display, 4 to 20mA with HART, PROFIBUS PA, FOUNDATION Fieldbus

-

Highest safety due to gastight feedthrough with capabilities up to SIL2/3, certified to IEC 61508

-

Cost savings with modular concept for easy replacement of sensor, display or electronics

Field of application

Two chamber aluminum or stainless steel (316L) housing.

-

Process connections: Threads, flanges or hygienic connections

-

Process temperature: -40 to +150°C (-40 to +302°F)

-

Measuring ranges: -1/0 up to to +40bar (+1.5 to +600psi)

-

Accuracy: ±0.075%, "Platinum" ±0.05%

-

International explosion protection certificates, WHG overfill prevention, SIL, EN 10204-3.1, 3-A, EHEDG, 3-A, ship building approvals

Features and specifications |

| Continus Liquids | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CATEGORIES

CONTACT US

Name: Sophie Wang

Mobile:+86 18681453433

Tel:+86 18681453433

Whatsapp:8613244706006

Email:sophie@meterbook.com

Add:Jingying Plot,Baoan District,Shenzhen City,Guangdong Province,China