Industry-news

Endress+Hauser Oxygen sensor COS61D-AAA1A3

|

Digital optical sensor based on the principle of fluorescence quenching, with or without Memosens protocol

Application

• Wastewater treatment plants

– Oxygen measurement and regulation in the activated sludge basin for a highly

efficient biological cleaning process

– Monitoring the oxygen content in the wastewater treatment plant outlet

• Water monitoring

Oxygen measurement in rivers, lakes or seas as an indicator of the water quality

• Water treatment

Oxygen measurement for status monitoring, e.g. of drinking water (oxygen

enrichment, corrosion protection etc.)

• Fish farming

Oxygen measurement and regulation for optimum living and growth conditions

Your benefits

• Optical technology:

– Minimum maintenance

– Maximum availability

• Sensor with digital signal processing:

– Calibration data saved in sensor

– High degree of EMC protection thanks to digital communication with the

transmitter

• Extended maintenance intervals and a high degree of longterm stability

• Intelligent self-monitoring guarantees reliable measured values

• No flow needed - measurement possible in still water

• COS61D - the Liquiline sensor

– Plug&Play: Safe communication based on Memosens protocol

– Optionally with M12 plug for fast connection to the transmitter

• COS61 - the Liquisys sensor

– Compatible with tried-and-tested COS31 with COM2x3W: Easy measuring point

changeover to optical technology

– Compatible with COS41 with COM2x3D with conversion kit

Endress+Hauser COS61D-AAA1A3 (COS61D-1020/0)

|

|

|

Measuring system

|

COS61D

A complete measuring system consists of the following components at least:

• Oxymax COS61D oxygen sensor

• Liquiline CM44x multi-channel transmitter

• Sensor cable, optionally available with M12 connector

• Assembly, e.g. flow assembly COA250, immersion assembly CYA112 or

retractable assembly COA451

Optionally:

• Assembly holder Flexdip CYH112 for immersion operation

• Extension cable CYK11

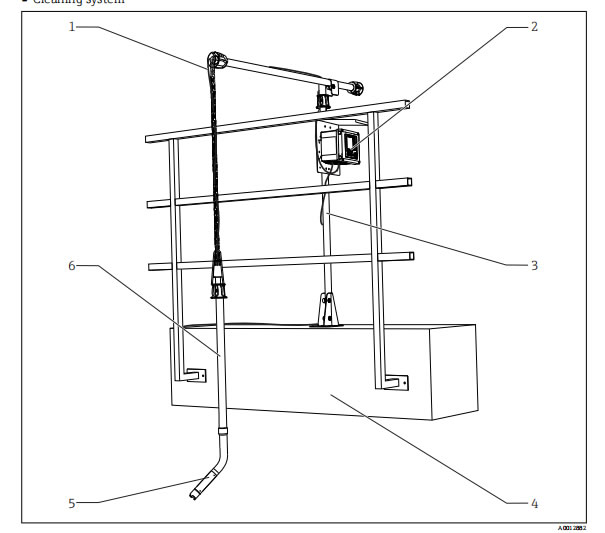

• Cleaning system

|

|

|

|

1 Sensor cable

2 Liquiline CM44x

3 Flexdip CYH112

|

4 Basin rim with railing

5 Oxymax COS61D

6 FlexdipCYA112

|

|

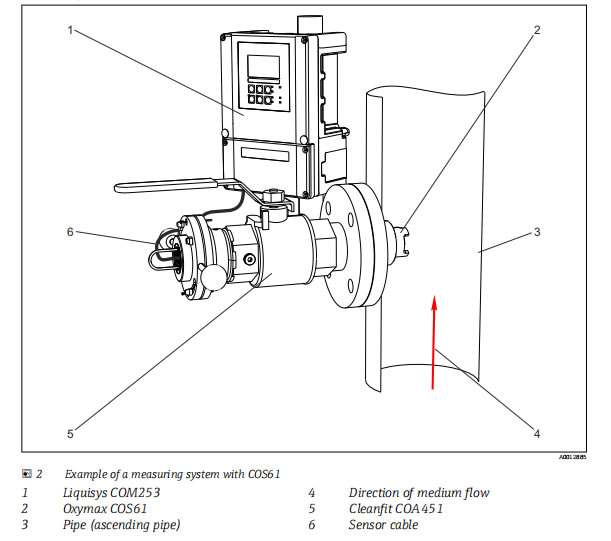

COS61

A complete measuring system comprises:

• Oxymax COS61 oxygen sensor

• Transmitter, e.g. Liquisys COM2x3-W

• Sensor cable

• Assembly, e.g. flow assembly COA250, immersion assembly CYA112 or

retractable assembly COA451

Optionally:

• Flexdip CYH112 assembly holder for immersion operation

• VS junction box (for cable extension)

• Cleaning system

|

|

|

|

|

Input

|

|

| Measured values |

Dissolved oxygen [mg/l, µg/l, ppm, ppb or %SAT or hPa]

|

|

Measuring ranges

|

Measuring ranges apply for 25 ˚C (77 ˚F) and 1013 hPa (15 psi)

With Liquiline CM44x, CM44xR, CM44P or with Liquisys COM2x3-W:

• 0 to 20 mg/l

• 0 to 400 hPa

• 0 to 200 % SAT

|

|

Power supply |

|

|

Electrical connection

|

COS61D

Connection data

• Sensor cable connected directly to the terminal connector of the basic module

• Optional: sensor cable plug connected to the M12 sensor socket of the transmitter

With this type of connection, the transmitter is already wired at the factory.

|

|

|

|

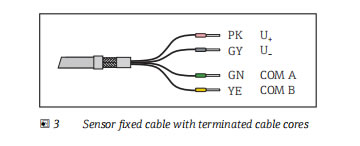

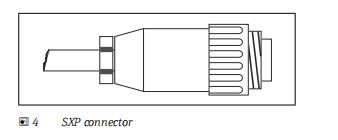

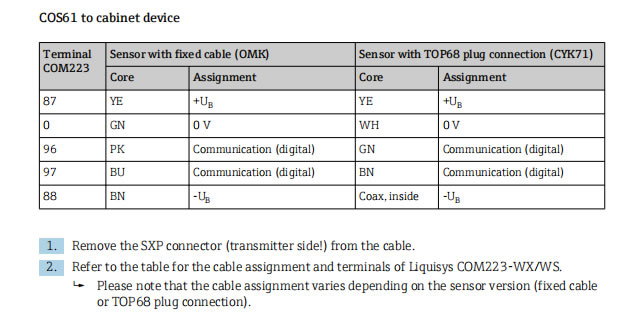

COS61 to field device

You connect the sensor directly to the transmitter via the special measuring cable with SXP

connector.

|

|

|

|

|

|

|

|

|

|

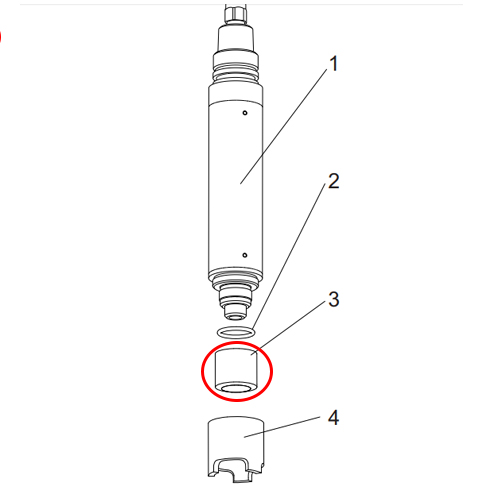

Operating life of sensor cap

>2 years (under reference operating conditions, protect against direct sunlight)

|

|

|

|

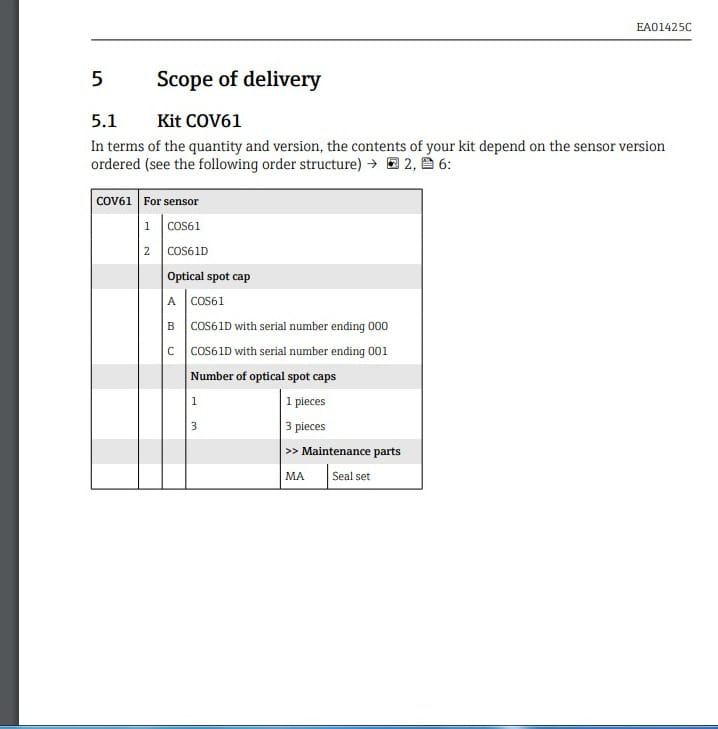

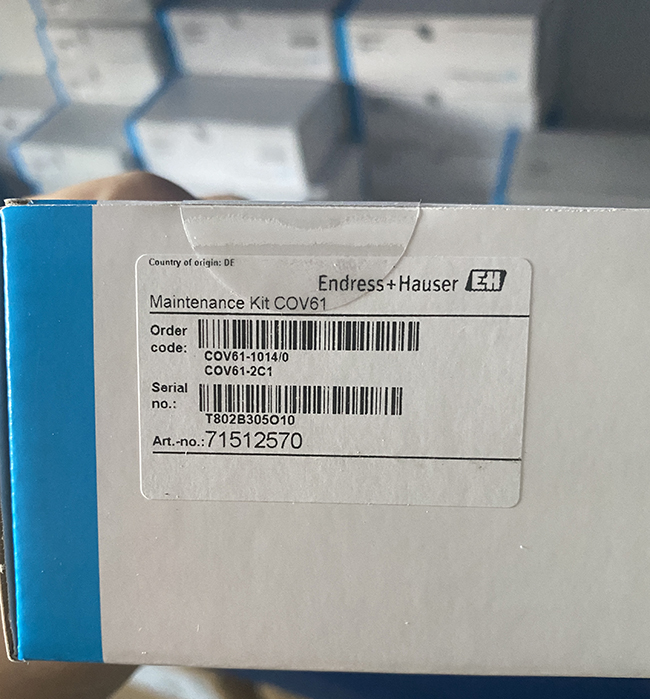

| COV61-2B1 replace 51518598 use for COS61D with serial number ending O00 |

|

| COV61-2C1 replace 51518598 use for COS61D with serial number ending O01 |

|

CATEGORIES

CONTACT US

Name: Sophie Wang

Mobile:+86 18681453433

Tel:+86 18681453433

Whatsapp:8613244706006

Email:sophie@meterbook.com

Add:Jingying Plot,Baoan District,Shenzhen City,Guangdong Province,China